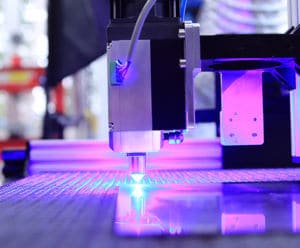

In relation to laser marking processes, the terms “laser etching” and “laser engraving” are frequently used interchangeably which confuses their different characteristics and uses. Despite both methods involving the use of laser power to make permanent marks on different substances, they differ in their basic principles resulting in unique aesthetic as well as functional attributes. This article will look at the differences between laser etching and laser engraving, applications for each, and how they can be used differently.

The Process of Laser Etching

Laser etching is a surface marking technique that involves removing material from the top layer of a substrate with absolute control. For this process, a high-powered light beam of lasers removes or ablates surface matter thereby creating shallow depressions or cavities in patterns desired. The etch depth might vary based on the laser’s power, speeds, and number of passes made on the material.

One of the main advantages of using laser etching is its ability to produce very detailed designs with great precision. This makes it suitable for applications needing complex logos, intricate graphics, or fine text marks. Besides metals, plastics, ceramics, and glass among others are some materials on which it can be done thus catering to clients from different industries.

Applications of Laser Etching

Branding and Product Identification

Laser etching is commonly used for branding purposes as well as product identification purposes. Such companies can engrave their logos or serial numbers onto their products to ensure that their authenticity and traceability are maintained.

Personalization and Customization

Since laser-etched markings are very precise; there is the possibility to personalize items such as jewellery,’ glassware electronics promotional items among others, hence enhancing individuality.

Decorative Applications

With this technology, one can create outstanding pieces e.g., architectural elements alongside decorative accents on metal surfaces, ceramics surfaces, and glasses. It therefore enables beautiful artwork through imprints created by these rays.

The Process of Laser Engraving

Laser engraving, on the other hand, is done by removing all material from a substrate to create a recessed or indented design. This process involves concentrating the laser beam intensely so as to vaporize or melt the material thus forming a cavity or groove of predetermined pattern or words.

Comparatively, engraving by means of lasers is a better option than etching as it produces more noticeable and deeper marks. This feature makes it ideal for applications requiring permanent effects. One can change the groove sizes of these engravings by adjusting the laser’s power, speed, and number of times it moves along the material.

Areas Where Laser Engraving is Applicable

Industrial Marking and Identification

Laser technology is often employed in marking and identifying many parts, tools, and equipment, especially within industries. It has to be legible even under harsh conditions.

Award and Trophy Engraving

These technologies are commonly used to engrave plaques and trophies among other appreciation items due to their depth and accuracy; aspects that ensure they remain visible over time.

Signage and Nameplates

Such tags which are typically made from materials like metals, plastics; wood-based materials, etc., still have a long life span. Hence, lasering them has become popular today.

Factors to Consider When Choosing Between Laser Etching or Laser Engraving

The choice between etching and engraving may depend on the material being marked. To have a good viewability as well as longevity some materials require deep engraved marks while others are best suited for etching.

Aesthetic Preferences

Laser etching generally leaves a subtle refined appearance whereas laser engraving provides a more obvious contrasting look. The desired aesthetic outcome should be considered when selecting the appropriate technique.

Depth and Durability Requirements

Where there is a need for markings to bear high tear or wear strength or perhaps withstand tough environmental conditions; laser engraving becomes preferable with its deeper longer-lasting marks.

Production Volume and Efficiency

Depending on the project requirements and production volume, one technique may be more efficient and cost-effective than the other thereby influencing the decision-making process involved in its selection.

Technological Advancements And Future Developments

This field changes continuously due to technological advancements that seek precision efficiency versatility driving towards laser marking. This means as the laser technology advances, we will see more improvements in both processes of laser etching and also in laser engraving.

One of these exciting advancements is the incorporation of artificial intelligence (AI) and machine learning algorithms into laser marking systems. With such sophisticated technologies, it could be possible to optimize power speeds beam focusing for different material designs so that precise consistent markings can be obtained apart from AI-assisted design pattern recognition capabilities that would hasten the complex design-making/implementation process while reducing lead time.

Additionally, there have been developments in hybrid laser marking machines which include both etching and engraving techniques within one platform. Consequently, users can switch between two methods on the same device allowing them to address a wider range of applications through just one setup.

Besides, fusing additive manufacturing techniques like 3D printing with laser marking introduces new dimensions for producing intricate customized items having embedded marks /engravings. In this way, medical device manufacturing, aerospace consumer product development, etc. could entirely change by bringing about an unparalleled level of customization traceability.

Furthermore, as there is increasing demand for solutions providing laser marking across different sectors; further advances and innovations are expected thus broadening our knowledge on how to use lasers for etching or engraving.

Conclusion

In the globe of laser marking, both processes have their distinct strengths and applications. While laser engraving is characterized by intricate detailed looks that are subtly visible, this makes it perfect for harsh environments and industrial use because it gives deeper sustainable marks via engraving. By understanding these differences and their respective strengths, businesses, and people can make the right choices to get what they want, such as making personalized gifts, branding items, or marking industrial elements. Finally, the decision between laser etching and laser engraving will depend on project requirements such as material compatibility and desired appearances or practicality.